ABOUT

KITCHEN COMPETENCY

Kitchen culture à la nobilia means: Quality made in Germany.

Experience intelligently engineered kitchens with superb design. Something for every taste, and at an attractive value for money.

OUR STANDARD

Nobilia builds intelligently engineered kitchens with excellent design and for every taste. For many people, nobilia kitchens reflect their attitude towards life. Our focus is always on: Quality.

In the planning department. In the production department. In the processing and customer service departments. At nobilia our goal is to provide every customer with exactly the kitchen they want. As unique as the people living in them.

Every nobilia kitchen is absolutely unique. Every single kitchen is individually planned and made with the utmost precision. Every nobilia kitchen is absolutely unique. Every single kitchen is individually planned and made with the utmost precision. More than 75 years of experience and a high degree of automation guarantee the consistently high level of quality.

COMPETENCY KNOWS NO BOUNDARIES

Nobilia is impressive both nationally and internationally: Which is why more than 8,000 trade customers in over 90 countries worldwide depend on the company. Almost every second kitchen – of the 783,000 produced annually – is exported.

Every market has its own laws. And nobilia always adjusts its trade structures to accommodate the requirements of the respective country. In whichever country – nobilia offers its partners quality kitchens with an outstanding value for money, which take into account the trends and preferences of worldwide markets.

INFORMATION

WE LEAVE NOTHING TO CHANCE

From receipt of goods to production and to delivery – nobilia has installed a sophisticated control system for all process steps, to guarantee the high quality of the products.

In addition, as many as 21 complete fitted kitchens are put through the paces of a quality audit every day. Quality, environmental protection and energy efficiency are essential elements of nobilia’s company philosophy.

CAREFUL HANDLING OF RESOURCES

The PEFC certification demonstrates nobilia’s dedication to an environment worth living in as well as responsibility in handling the valuable raw material wood. You can always count on: Our processed derived timber products all come from sustainably managed forests and controlled sources.

WE MAKE COMPLETE KITCHENS

Nobilia offers the retail market a complete package kitchen from a single source: with intelligent accessories, attractive built-in sinks and a wide range of electric appliance brands from entry level price to the premium high-end segment.

DELIVERY IN A NUTSHELL

We achieve the highest degree of delivery quality and adherence to delivery dates thanks to our own “white” vehicle fleet. Our highly qualified drivers ensure professional and secure furniture transport at all times. 411 Drivers.

FACTS

KITCHEN CULTURE À LA NOBILIA

We build intelligently engineered kitchens with superb design. nobilia kitchens capture many peoples’ attitude towards life with something for every taste, and they also impress with their attractive value for money.

FIGURES, DATA AND FACTS

There is 75 years of experience and the know-how and lifeblood of more than 4,200 employees in every one of our kitchens. All this and much more have made us the market leader and Europe’s largest kitchen manufacturer.

FOUNDING

- Company founding : 1945

- Founder : Brothers Johann and Willy Stickling

MARKET DATA

- Sales volume : EUR 1.482 billion

- Export ratio: 53,1 %

- Trade customers: More than 8,000 worldwide

- Employees: Employees:

PRODUCTION

- Production sites : 2 in Germany

- Complete marketing : Approx 5,500 electric appliances/day

PRODUCTION AREA:

- 385,000 m², of which:

- 110,000 m² in plant I, Verl-Sürenheide

- 140,000 m² in plant II, Verl-Kaunitz

- 35,000 m² in plant III, Gütersloh

- 100,000 m² in plant V, Saarlouis

PRODUCTION FIGURES 2021:

- 830,000 kitchens/year

- 8,300,000 units/year

- 1,750,000 worktops/year

- 3,800 kitchens/day

OWN VEHICLE FLEET

1. TRANSPORT AND LOGISTICS

- 227 lorries and 900 semi-trailers

- 411 qualified trained drivers

2. FREIGHT VOLUME

- 3.15 million m³/year

3. TRAVEL DISTANCE, LORRIES

- 20.6 million km/year

QUALITY

- Certified energy management : according to ISO 50001

- Certified quality management : according to ISO 9001

- Certified environmental management : according to ISO 14001

- GS quality seal for tested safety “Golden M“ : From the DGM, Deutsche Gütegemeinschaft Möbel (German quality control association)

- "Furniture made in Germany"

- Environmental seal “Der Blaue Engel” (blue angel eco label)

- TSCA Titel VI compliant / CARB2

- PEFC seal : for the use of wood from sustainably managed forests

- Emission Class DGM

HISTORY

OUR ROOTS

nobilia kitchens have been a part of our home for generations. Join us on a journey through time as we explore 70 years of company history.

FOCUS ON FITTED KITCHENS, 1967

Since the company converted to a limited partnership in 1962, it has carried the name NOBILIA-Werke J. Stickling KG. Johann Stickling’s younger son Werner Stickling joins the business. The number of employees increases to 145. Just under a quarter century after it was founded, nobilia now specialises exclusively in fitted kitchens.

GENERATIONAL CHANGE, 1970

Johann Stickling hands over the leadership responsibility to his sons Heinz and Werner Stickling. In order to further develop production, a new plant with an initial production area of 7,000 m² opens on a property measuring 51,000 m² in Verl-Sürenheide on the occasion of the company’s 25th anniversary.

QUALITY

MADE IN GERMANY

From receipt of goods to production and to delivery – nobilia has installed a sophisticated control system for all process steps, to guarantee the high quality of every single kitchen.

In addition to the testing stations, up to 21 complete fitted kitchens are put through the paces of a quality audit every day. Quality, environment and energy have been core to our company philosophy since our very beginning. Every single nobilia kitchen meets the stringent international quality, environment and energy guidelines.

Stress test for kitchens – proof of quality is in the quality control testing laboratory.

Furniture, components and materials must prove themselves fit for daily wear and tear through extensive testing in our own QC testing laboratory. Indeed, for 15 years worth of wear and tear. All materials used are tested for this minimum service life.

QUALITY ASSURANCE

Regular product audits, ramp audits and return shipment reviews are important components of our consistent quality assurance. A quality circle group with customers as well as workshops for trade partners and collaborating fitting installation companies also ensure the highest nobilia quality.

AWARDS

AWARDS AND QUALITY SEALS

From the very first glance nobilia quality can be seen, felt and experienced every day. Our awards from independent testing institutes are the proof.

CERTIFIED MANAGEMENT SYSTEM

On a regular basis, TÜV Rheinland / LGA InterCert reviews and certifies our quality management system according to ISO 9001, our environmental management system according to ISO 14001 and our energy management system according to ISO 50001. The ISO 9001 norm establishes the standards for a quality management system in order to satisfy customer requirements and ensure product quality. This seal represents well-designed workflows, which we have optimised especially for the development, manufacture and sales of kitchens.

The ISO 14001 norm for environmental management systems helps improve a company’s environmental performance. Companies can continuously improve their energy efficiency with the energy management norm ISO 50001. By following the energy management standard ISO 50001, companies can continuously improve their energy efficiency and reduce their CO2 emissions. All three of the certificates issued by TÜV Rheinland are globally recognised standards.

GS QUALITY SEAL FOR TESTED SAFETY

This certificate is awarded by LGA Nürnberg (furniture testing institute). The LGA belongs to the TÜV Rheinland Group and is Europe’s largest and most important furniture testing institute. The GS quality seal for tested safety is a voluntary safety seal that has meaning far beyond the borders of Germany.

In the area of consumers and occupational health and safety, it provides the guarantee that the safety requirements have been met and are regularly reviewed by an independent institute such as the LGA. LGA product certificates for furniture, furniture parts, components and accessories are a way of identifying tested and monitored quality, product safety, durability, user-friendliness and material stability.

“GOLDEN M“

The DGM Deutsche Gütegemeinschaft Möbel - (German furniture quality seal) have tested nobilia in accordance with RAL-GZ 430. Following this test, nobilia was awarded the RAL quality seal, the "Golden M". This ensures that each kitchen leaving the plant meets today’s expectations and quality requirements for a long life, stability and health and environmental aspects.

"FURNITURE MADE IN GERMANY"

Since August 1, 2020 end consumers have discovered a new label on the market, which gives them information about furniture quality: “Furniture Made in Germany” is the geographical origin mark in accordance with RAL-RG 0191, which labels German-made furniture that meets verifiable, strictly defined criteria. This certificate requires proof that the design, assembly and quality testing of the furniture takes place in Germany. As often before, nobilia is once again among the first kitchen furniture manufacturers to be distinguished with the new “Made in Germany” label.

BLAUER ENGEL (BLUE ANGEL ECO LABEL)

In July 2012 our company was the first kitchen furniture manufacturer awarded the eco label “Der Blaue Engel” (blue angel). This mark of the German Federal Environmental Agency promotes the concerns of environmental and health protection as well as consumer protection.

The products and services which are distinguished are those –– when viewed holistically – which are particularly environmentally friendly and at the same time meet the high standards for occupational health and safety as well as usability. The “Blaue Engel” (blue angel) was awarded to the following ranges: 253, 312, 317, 351, 371, 382, 406, 526, 545, 555, 566, 615, 648, 706, 808, 917, 977 and 985.

TSCA TITEL VI COMPLIANT / CARB2

For the manufacture of its furniture nobilia uses only derived timber products which meet the stringent U.S. EPA Formaldehyde Emissions Standard of the TSCA Title VI Toxic Substances Control Act.

With this step, our company fulfils the American requirements - in effect since June 1, 2018 - for the further reduction of formaldehyde emissions from derived timber products. The maximum permissible values from TSCA Tile VI correspond to the CARB2 (California Air Resources Board) ” standard from California. The furniture is labelled with the information “TSCA Title VI compliant.”

PEFC /04-31-1281

Since July 2009 nobilia is the first ever kitchen manufacturer certified in accordance with PEFC (Programme for the Endorsement of Forest Certification Schemes). In this way, nobilia documents its dedication to an environment worth living in as well as responsibility in handling the valuable raw material wood.

Since the derived timber products processed all come from sustainably managed forests and controlled sources. Forest certification provides the guarantee that the wood products that consumers purchase are not coming from questionable sources nor from overexploitation, but come from managed semi-natural forests. By applying for PEFC certification, nobilia kitchens demonstrates to the customer a sense of responsibility for our environment.

CLIMATE AGREEMENT OF THE FURNITURE INDUSTRY

We put the focus on sustainability at nobilia. The same goes for the subject of greenhouse gas emissions. Here, it is of primary importance to face the responsibility – alongside other manufacturers – that this generation has toward future generations and the environment.

In 2016 the DGM (German quality control association) initiated the ”Climate Agreement for the Furniture Industry” and nobilia is an established member. In order for the CO2 footprint to gradually be reduced and ideally neutralised, it is important to nobilia to take a pioneering role in making this topic public and raising awareness.

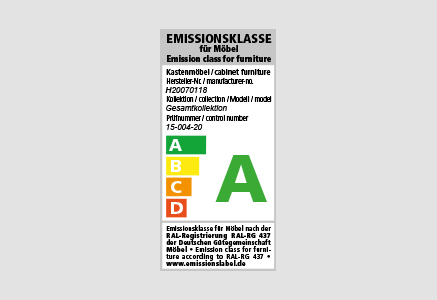

EMISSION CLASS DGM (GERMAN QUALITY CONTROL ASSOCIATION)

Having met all award requirements, nobilia's kitchen furniture was awarded the highest emissions class of A by the Deutschen Gütegemeinschaft Möbel e.V. (German quality control association). The RAL emission label informs consumers about emission of harmful substances and protects them from health hazards.

GOGREEN CERTIFICATE

The entire mail and package dispatch is taken care of by the CO2 neutral GOGREEN services of the German postal service and DHL. With this, nobilia offsets the CO2 emissions created during transport. The offset is certified through an independent certification company (Societé Général de Surveillance, SGS) according to ISO 14064.