ABOUT

WHO WE ARE

Present and past is found in Julia MarmiJULIA MARMI is the Piasentina Stone: the fragrances and harshness of the stone has for decades been passed on from the hands of skilled stone-cutters to modern trials, mixing ancient knowledge and modern curiosities to offer unique pieces, carefully finished off, skillfully made from shapeless cube blocks to guarantee the highest quality.

OUR STORY

Mario Laurino matures his passion for stone since he was young: on 1 July 1940 he is already working in quarry alongside his grandfather where he remained for seven years. In 1965 he resumed this activity in an entrepreneurial form and founded, with the passionate support of his wife, Julia Marmi.

During this period he went to Tarpezzo and Tarcetta, while in 1972 the quarry of S. Ermacora in Torreano was opened. The opening of the Clastra quarry dates back to 1980 and is progressively expanding. At the beginning of its activity, Julia Marmi had few machines, but could count on the experience of many specialized stonecutters, who returned to Italy after years of work abroad.

Today the machine park has been completely renovated and production has opened up to new collaborations in the field of design but without ever forgetting the value of handmade work.

PIETRA-PIASENTINA

PIASENTINA STONE

Fruit of a whim of the nature of the Eocene period, the Piasentina Stone is compact and strong, with recognized characteristics of non-freezing, robustness, good workability and particular chromaticity, a warm gray with possible shades of brownish red and white veins, which varies appearance at vary surface processing.

From the saw to the polished, to the flamed and brushed to more traditional or innovative finishes and allowing for numerous combinations on the same material.This feature, combined with its performance characteristics, can meet the many design solutions and applications of creative Designers and Architects.

A NOBLE MATERIAL

Piasentina Stone is the construction and facing stone par excellence in the architecture of Friuli, where archaeological findings bear witness to the use of this stone as early as Roman times. In the 16th century the stone was also used for the monumental works by Palladio. Today Pietra Piasentina is a construction material appreciated and used around the world.

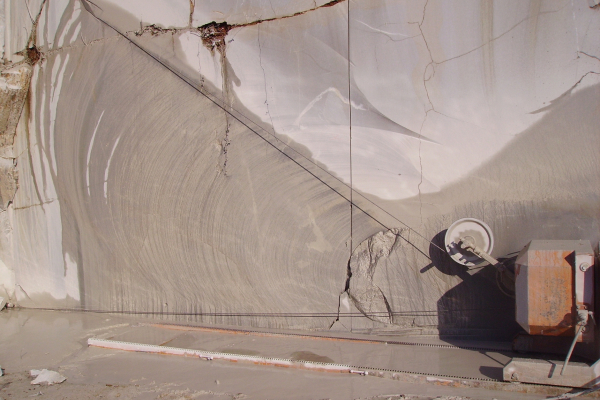

CAVE

THE ENVIRONMENT

Our Work In Respect Of The Environment The Piasentina Stone Is Quarried In A Small Area Of The North-eastern Foothills Of Friuli, In Open-air Quarries, Operating In A Manner Of Respecting The Environment And A Correct Environmental Recovery.

Julia Marmi owns three active quarries of Piasentina stone, all as permitted within the guidelines of the Friuli Venezia Giulia region.The Julia Marmi quarries are also green areas, where stone is extracted but becomes areas for a theater, walking space, picnic areas whereas giving back to the nature of what the nature gives us.

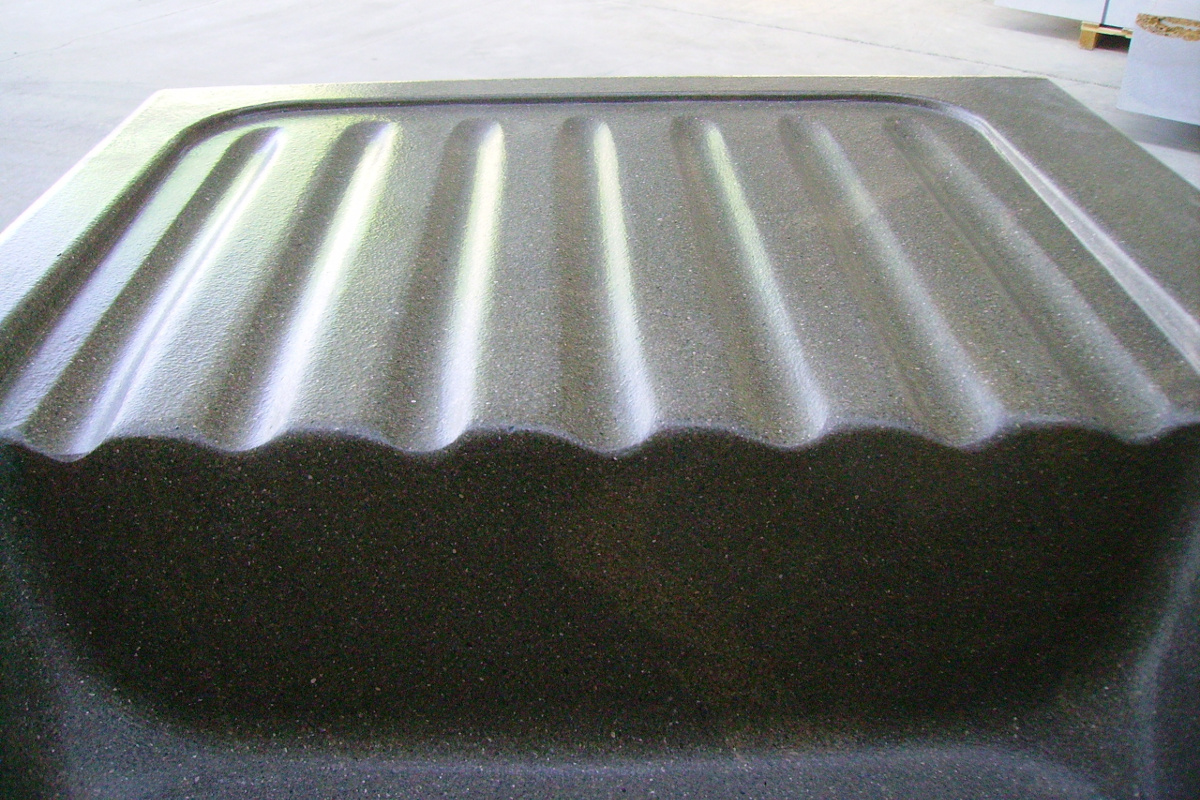

FINISHES

ANTIQUED J

The antiquing J is the result of an accented random flaming and subsequent brushing.The final effect recalls the surfaces of the ancient artifacts on which the signs of past time and wear are imprinted; compared to the hand-aged it is darker and softer, more regular.