ABOUT

Comfort Made of Wood

Wooden chair factory. We produce chairs, armchairs, sofas and tables for hospitality and healthcare centers. We're specialized in contract. We take comfort, quality, technique, elegance and luxury and turn it into a chair. Specialized in high end quality chair for Contract and domestic use.

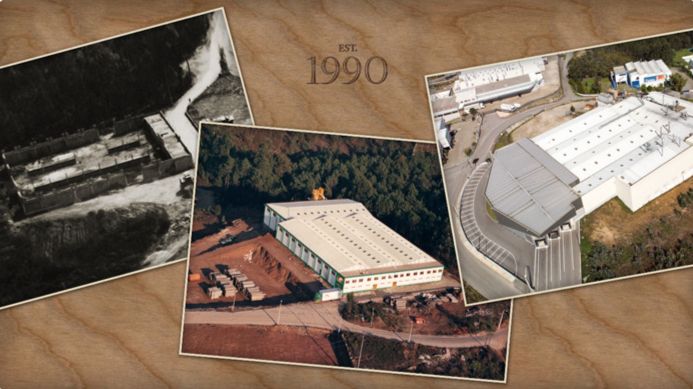

HISTORY

CMcadeiras is a company based in Rebordosa, Paredes - a region of Portugal with a very strong and ancient tradition in the manufacture of furniture pieces. Manuel Campos decided to create his own furniture company - Campos & Filhos (currently known as Ducampus)

The company's origins date back to the 1940s, when Mr. . Decades later, in August 1990, the decision was made to expand the operation, in order to respond to the growing demand of the market for wooden chairs; thus CMcadeiras was born.

PRODUCTION

WOOD

WOOD SELECTION

PRESSES

SANDING

LABELING

RETOUCHING

DRYING

PACKING